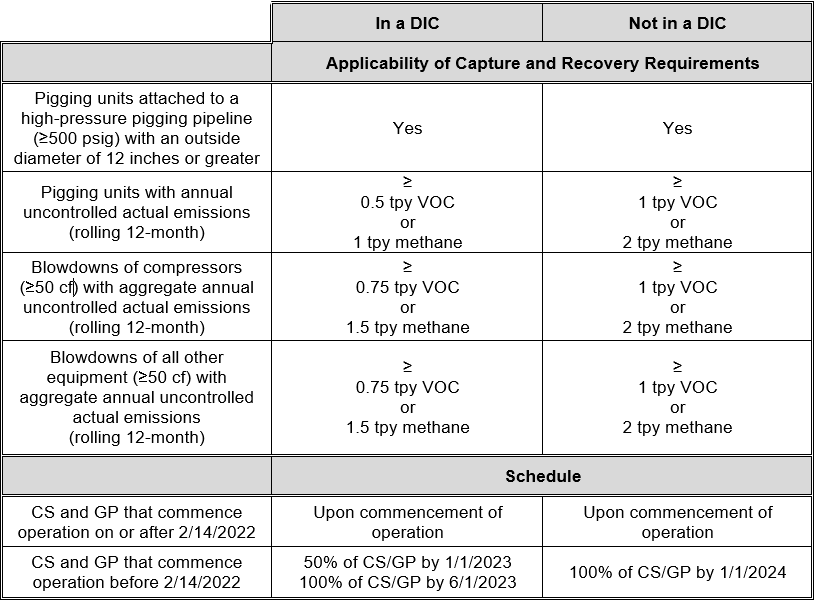

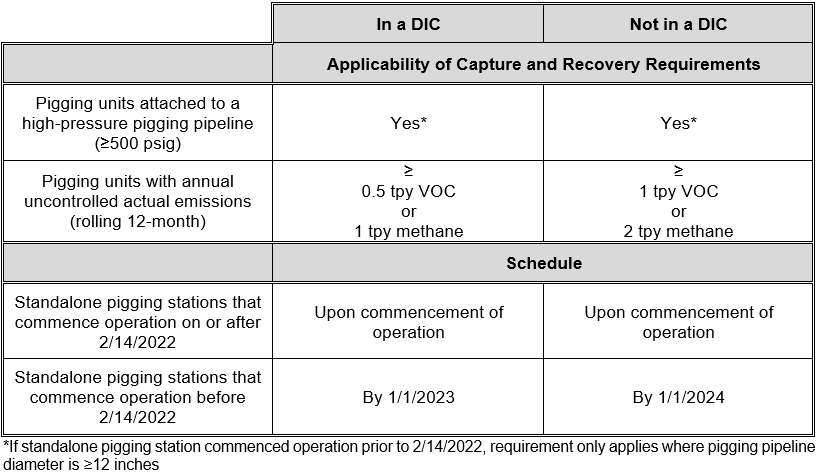

In addition, for equipment not initially subject to these requirements, the requirements become effective within 60 days of the first day of the month for equipment which increases hydrocarbon emission levels to the above indicated thresholds after the applicable compliance date of the rule.

Capture and recovery requirements (II.H.3.)

During normal operations (excluding planned emergency system shutdown testing operations), emissions from pigging and blowdown activities must be captured and recovered. Blowdowns of storage vessels, pressure vessels, or process vessels operating below 20 psig are not required to be captured and recovered. Residual emissions from depressurization of the blowdown volume remaining after capture and recovery techniques have been implemented are considered in compliance.

Where a compressor station (“CS”) or a natural gas processing plant (“GP”) is connected to an electric grid, capture and recovery techniques must be powered by non-emitting equipment. If technically or economically infeasible, the operator must keep records of the determination made.

If capture and recovery of pigging/blowdown emissions is not feasible, an operator may request Division approval to use a control device to comply with this section. If such activities are controlled as of 2/14/2022, or if an application was pending with the Division as of 12/31/2021 to control such activities, then no further Division approval is required. The Division must be notified by 3/31/2022 that control devices will be used to comply with this section.

Midstream operators must design and operate CS, GP, and standalone pigging stations that commence operation on after 1/1/2023 to maximize capture and recovery of routine pigging/blowdown emissions and keep a record of the analysis undertaken at the time of facility development.

Required best practices (II.H.4.)

Beginning 1/1/2023, Midstream operators are required to use best practices for all pigging/blowdown operations at their facilities, including standalone pigging stations and midstream pipelines not located within the boundaries of a CS or GP. The following list highlights some (not all) of the required best practices:

- Utilizing liquids management system for pigging units in the Nonattainment Area (“NAA”)

- Rerouting gas to low pressure systems where feasible for pipeline blowdowns

- Using short pig barrels

- Planning for venting-reduction steps, such as pipeline pump-down techniques

- Coordinating operational repairs and routine maintenance

Natural gas processing plants requirements (II.I., III.C.3.d., III.D.4.)

Leak Detection and Repair (II.I.)

Beginning 1/1/2023, GPs not subject to the requirements in Regulation 7 Part D, Section I.G. must comply with New Source Performance Standard (“NSPS”) OOOOa LDAR requirements for GPs unless subject to NSPS OOOO requirements for GPs.

For leaks placed on delay of repair (“DOR”), operators must repair the leaks within two (2) years or the applicable timeline in NSPS OOOO or OOOO/a, whichever is earlier. The operator must also take action(s) to mitigate emissions from DOR leaks where technically feasible.

Natural gas-actuated pneumatic controllers (III.C.3.d., III.D.4.)

All pneumatic controllers, located at GPs not subject to the requirements of Section III.C.2 and placed in service on or after 1/1/2023, must be zero-bleed (unless allowed in Section III.C.3.a.iii).

All pneumatic controllers placed in service prior to 1/1/2023 at GPs must be replaced or retrofit with a zero-bleed option by 1/1/2024 (unless allowed in Section II.C.3.a.iii).

For all pneumatic controllers that remain in service at natural gas processing plants with a bleed rate greater than zero (0) for process/safety purposes, the operator must tag and inspect the controllers monthly beginning 3/1/2023. Additionally, the operator must submit a justification to the Division:

- By 3/1/2023 for pneumatic controllers that were placed in service prior to 1/1/2023

- 30 days prior to installation for pneumatic controllers placed in service on or after 1/1/2023

Beginning 1/1/2023, operators must inspect gas-driven pneumatic controllers at GPs at least quarterly using an approved instrument monitoring method.

Finally, beginning 5/31/2024, operators of GPs must submit annual reports regarding their pneumatic controllers’ inspection and enhanced response activities.